+86 576 84086666+86 576 84086666

Blown Fabric Line

DKM Hydro-charging Melt Blown Fabric Line

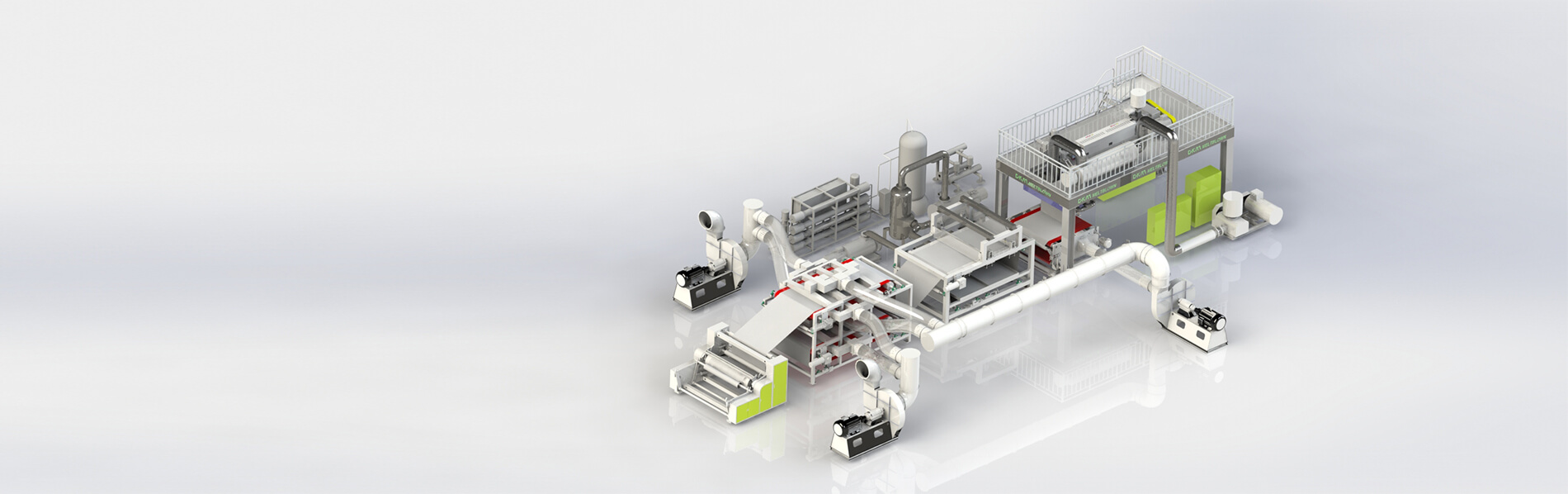

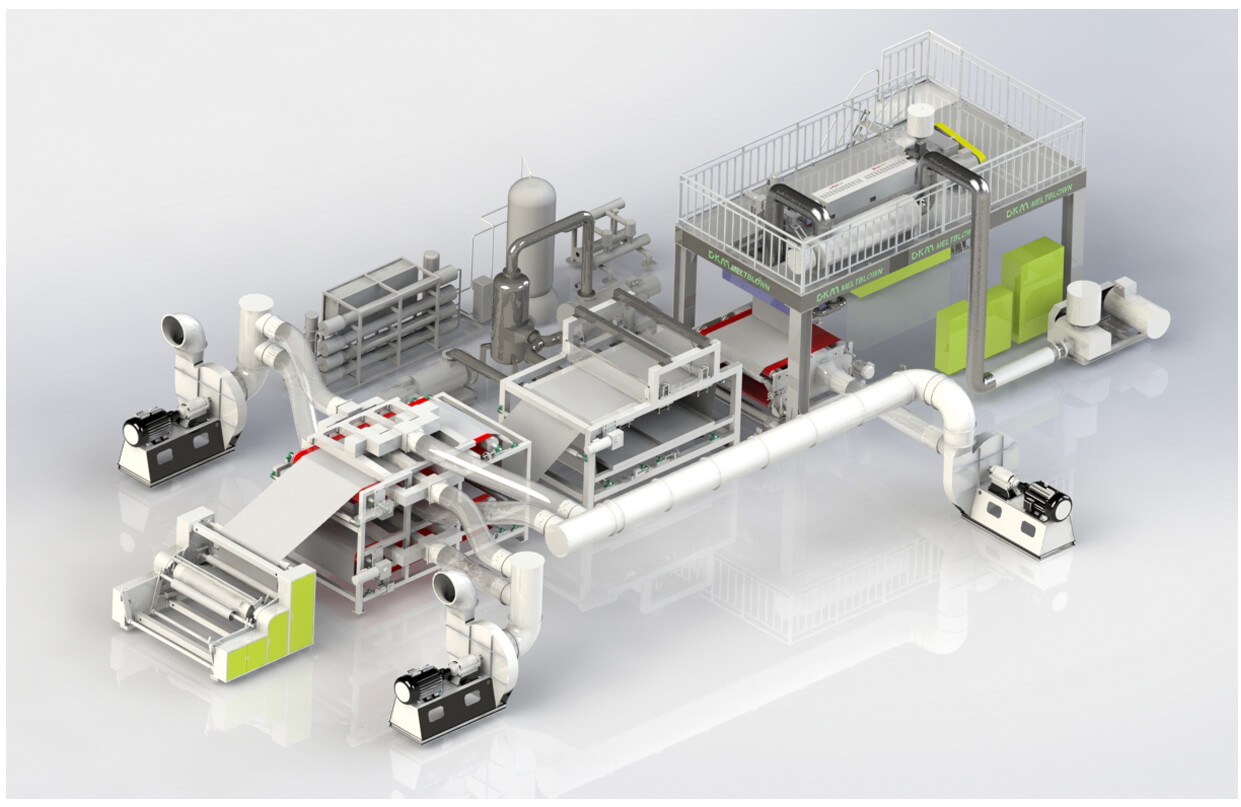

DKM complete one piece unit hydro-charging melt blown fabric line, compared with DKM Hydro-Charging Machinery, achieves less space, energy consumption and cost thanks to special hydro-charging system designed by DKM R&D team, which helps you manufacturing FFP2+ / KF94+ melt blown fabrics much more efficiently.

DKM Hydro-charging Melt Blown Fabric Line Four Highlights

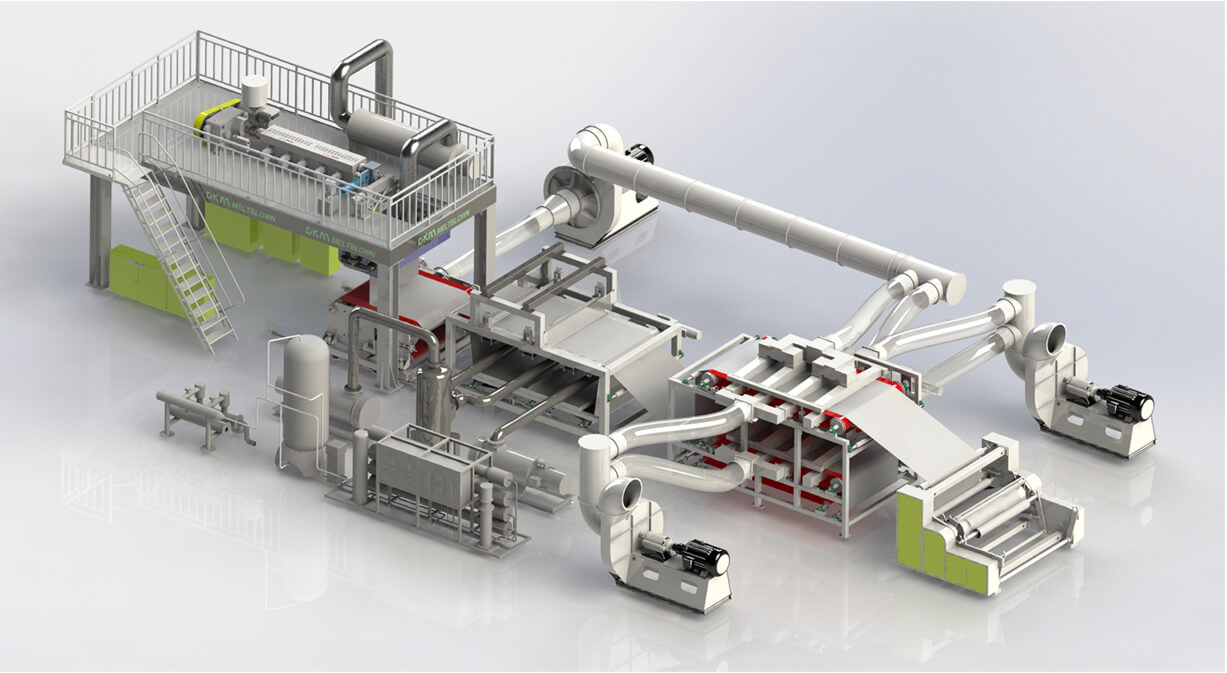

The whole line is designed with hydro-charging system, considered comprehensively for customers. You could find the advantages compared with the traditional hydro-charging lines.

Less Floor Space

Cost Saving

Cost Saving

DKM special design for saving line foot space and cost (unwinding machinery and rewinding machinery are unnecessary).

DKM fabric dryer is applied with multi-layer design, so the length of it is just about 5 meters, which saves the time for delivering fabrics between traditional dryers as well, make the production more automatic and efficient.

DKM fabric dryer is applied with multi-layer design, so the length of it is just about 5 meters, which saves the time for delivering fabrics between traditional dryers as well, make the production more automatic and efficient.

Energy Saving

More Output

More Output

The hot air of melt blown process is utilized with drying process of hydro-charging to save the energy.

DKM fabric dryer based on hot air convection drying reduces the drying time, and thanks to precision moisture sensor, increasing the output of quality fabrics much.

DKM fabric dryer based on hot air convection drying reduces the drying time, and thanks to precision moisture sensor, increasing the output of quality fabrics much.

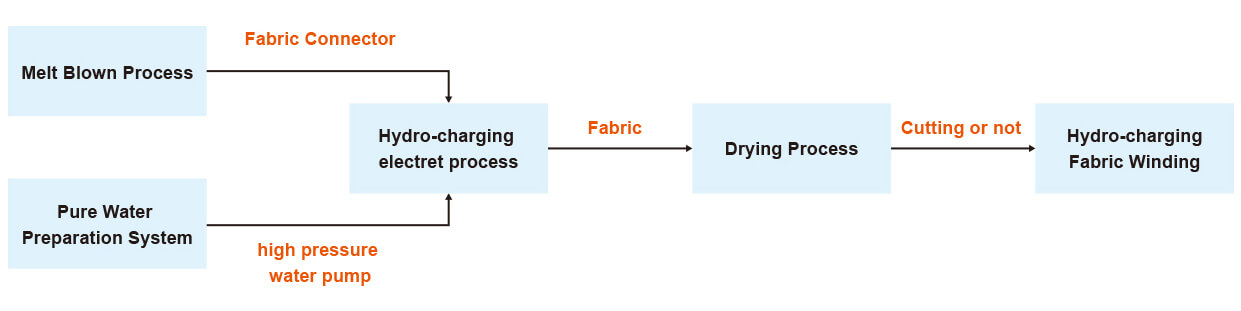

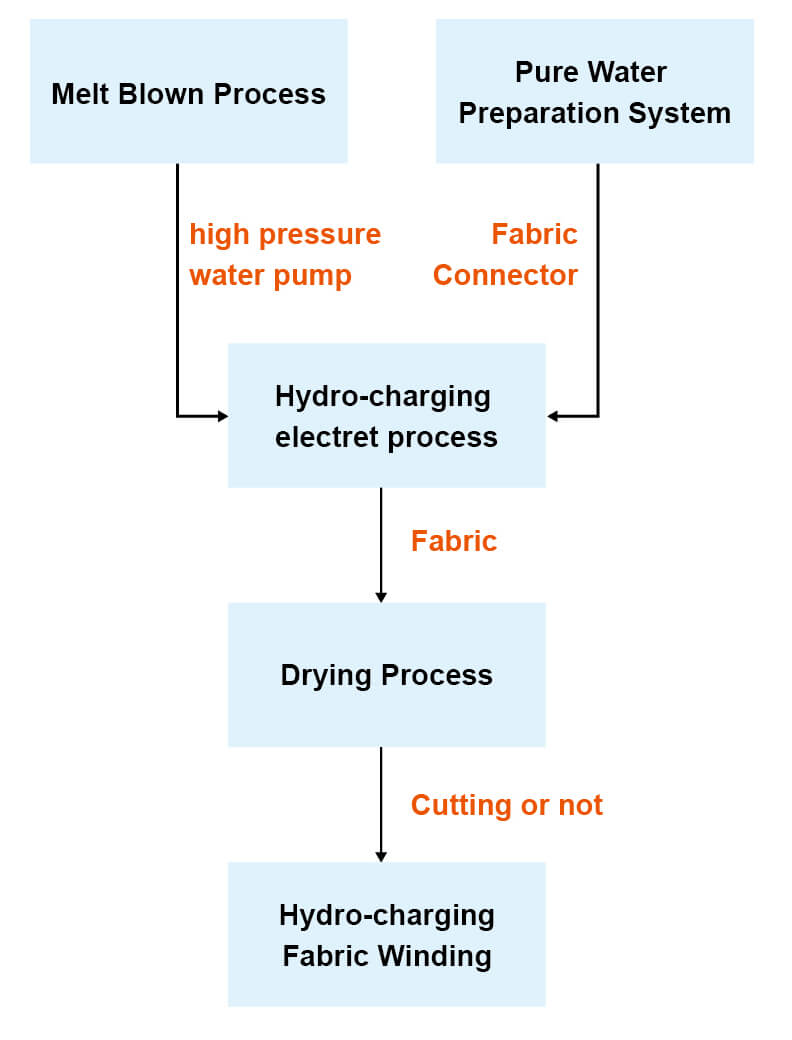

DKM Hydro-charging Melt Blown Fabric Line Process Diagram

DKM improves the whole process of hydro-charging melt blown production to increase the return on investment and keep the high quality of fabrics in line with high-end market demand: stable on electret, better permeability and low resistance.

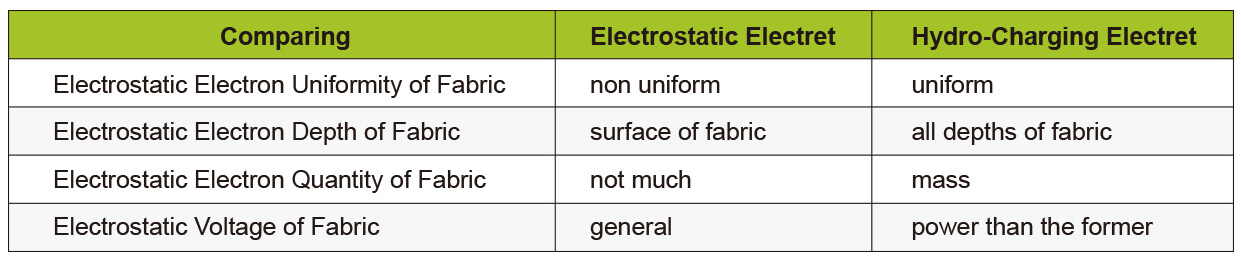

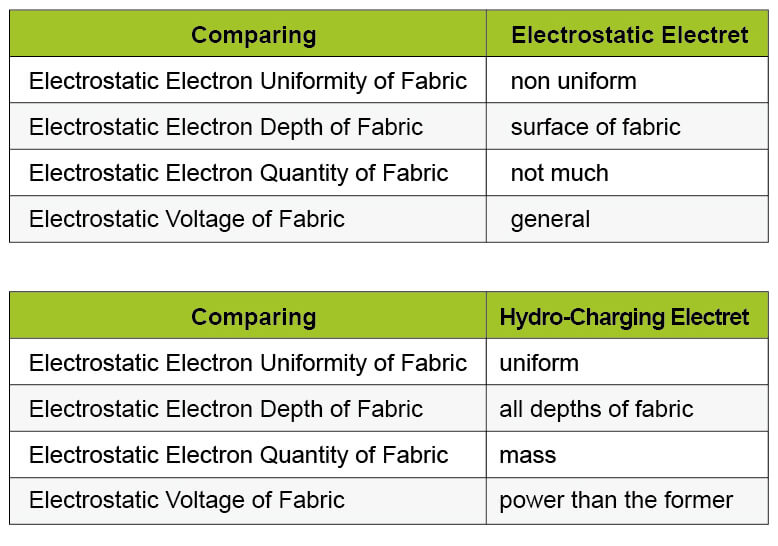

The Difference between Hydro-Charging Method Electret and Electrostatic Electret

Note: the differences are based on the same melt blown fabric before the electret process.

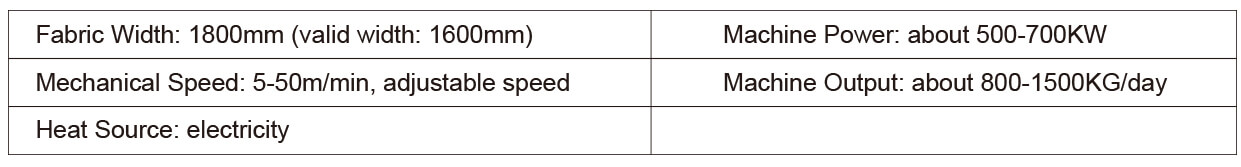

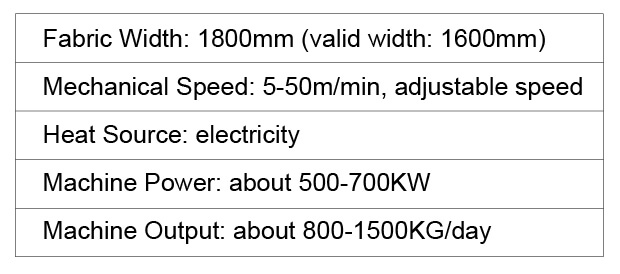

For DKM1600 Hydro-Charging Method Melt Blown Fabric Production Line

DKM Service

DKM provides comprehensive service and support to guarantee that you get the quality hydro-charging melt blown line which would be stable running for long term.

Get in touch with DKM for Hydro-charging Melt Blown Fabric Line or any questions.